This week’s guest blog comes courtesy of Jane Picciano, who is a Sustainability Champion working in the Library Services Team at King’s.

King’s Food waste goes to Anaerobic Digestion (AD), which helps to meet the following Sustainable Development Goals:

This is the story of what happens to all food waste from King’s!

I got a chance to join the King’s Sustainability team on a visit to an Anaerobic Digestion plant (Agrivert) in Virginia Water which was coordinated with Simply Waste, the food waste collection company for King’s. The tour was led by Charlie who has worked in the recycling industry for over 15 years, starting in local recycling then moving into food specific recycling.

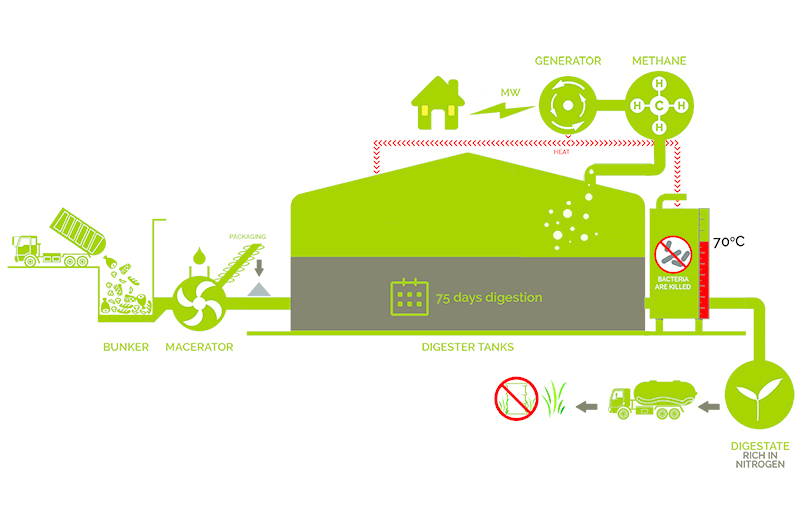

This plant is where all King’s food waste goes to be ‘digested’ then reused as fuel in a methane gas form to power their machines, with any extra sold back to the grid to power 4400 local homes, and as compost to local farmers.

Big trucks drive up to the entrance, as they arrive they punch in a designated code which identifies which company they come from. A scale under the driveway weighs the vehicle and then the vehicle is given the green light to go into the recycling bunker. Once inside, the food waste load is dumped into a deep concrete ‘mouth’ where the process of decomposition begins.

Once the food waste is dumped into this concrete stomach, the waste is mixed with water to make it easier for any plastic contamination to be sieved out. This is where the plastic contaminated waste comes out and next to it a photo of said waste. The plastic waste is sent to an Energy from Waste Plant.

We were told that most food waste recycling companies prefer food to be in plastic bags rather than biodegradable bags as they are very hard to separate from the food. Biodegradable bags stretch and don’t break as easy which makes them dangerous to the machinery that chops everything up finely for digestion. In addition, they contain more water than plastic, so cannot be burned effectively to get energy from waste. If you look closely at the picture of plastic waste, you can see how big the waste is and how easy it is to sift it out.

Once that is all done, the food waste sludge goes through one more pipe and any tiny bits of plastic and grit not caught by the grinder is siphoned out. After this, the waste is ready to go and gets fed into one of the holding tanks (or ‘Stomachs’ of the plant).

The food waste is now ready for a long ferment (75 days in fact) in one of the five tanks they have. Having the luxury of five tanks gives Agrivert the choice to choose which one to use first and helps them if for some reason there is any kind of mechanical issue or if one of the tanks becomes ‘sick’.

Anything can make a tank sick – we were told to think of it like our own digestive system, in that when you have something that doesn’t agree with you, you might need to a bland diet of something like chicken and rice for a few days to get your stomach back to normal. If one of their batches does gets sick, Agrivert has a ‘chicken and rice’ equivalent that they feed the tank and they soon feel better and are healthy again and they can get back to work! Making sure that the food waste is of a wide variety is important, if the tanks just receive one type of food – such load of bread or curry, the chance of getting sick increases (just like if a human only at one type of food for a long time). Therefore, Agrivert makes sure to balance what the tank receives to reduce the change of it getting sick before the ‘chicken & rice’ is necessary.

You will notice that all the tanks have soft domes on them, this is where the gas created by the process collects and is then used to power the Agrivert machinery with any extra sold back to the grid. The power generated from their left-over gasses power up to 4500 local homes per year. The soft domes help identify when there is a problem with the tank, as it will appear sunken and not fully inflated as seen in the images below.

You can see the large motors on the outside of the tanks. These are blades that move the food sludge and make sure it is turning continually and kept warm throughout the whole process (at body temperature – around 37 degrees). The blades are different sizes and heights so that everything moves around and utilizes the whole tank.

The two long implements you can see above are examples of what the blades that churn the food waste around the tank look like.

It was interesting to see the re-purposing of shipping containers; these are being used as heat diffusion containers and the had several more as office and staff room space. The entrance has room for a couple of small offices, a large meeting room and presentation space as well as a kitchen and toilet facilities for the staff and guests.

The last bit of the tour took us past the huge pipe that you see below; we were told that if this pipe ever stops working it would lead to a very loud and dangerous explosion – it means that the methane expelled from the tanks is not moving freely around and has stopped, building up pressure and finally, exploding. Thankfully that’s has never happened at this Agrivert plant but has happened at others.

And this is the story of what happens to the food waste collected at King’s College London!

If you get the chance, I would recommend you go and see how one of these plants operates (The Sustainability Team put on one or two trips to King’s waste facilities a year, follow Sustainability Team social media and newsletter to keep up to date on the next). If anything, visiting one of these plants will give you hope for the future of recycling and show you that it is possible to turn waste; food or otherwise into reusable energy that can power homes and fertilize crops.

The only thing I would strongly suggest is: bring something to cover your nose & mouth, as the smell is overpowering and it lingers on clothes.

I can’t even describe it. 🤢

Jane Picciano, Sustainability Champion Gold, Maughan Library